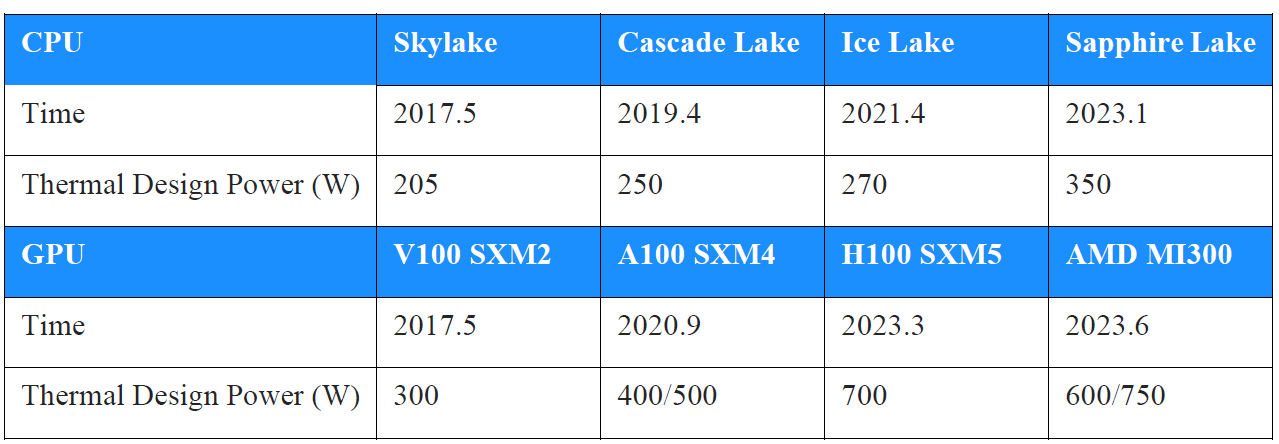

ChatGPT gains immense popularity in 2023, tech giants worldwide are engaged in fierce competition to discover the potential applications of AI. The shift from training models to inference models, coupled with escalating computational demands, is placing greater emphasis on the performance of CPUs and GPUs.

Enhanced data center performance invariably leads to higher power consumption, resulting in an upsurge in heat generation. Each degree Celsius increase in operating temperature brings about a decline in performance and an augmented power consumption.

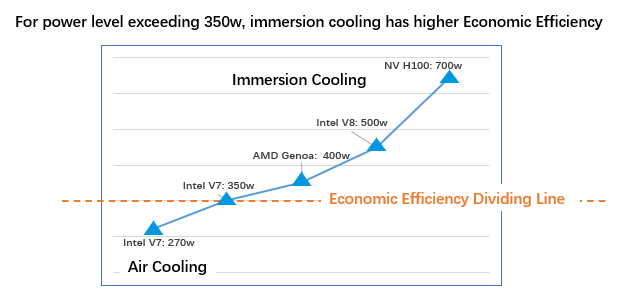

Unfortunately, traditional methods of cooling such as air cooling and cold plate cooling are inadequate to meet the heat dissipation demands arising from the progress in computing power. Data centers are now grappling with heat dissipation bottlenecks. It could be contended that those who excel in heat dissipation technology hold the crucial solution to surmounting the computational power bottleneck.

Immersion cooling technology has emerged as a compelling answer to the cooling challenge in the data center industry. Currently in its early adoption phase, this technology has garnered significant attention. Experts believe that within the next four years, it will become widely adopted, leading to exponential market growth. Market analysts project that the immersion cooling market, currently valued at $251 million in 2021, will surge to over $1.6 billion by 2027.

What are the benefits of immersion cooling?

Immersion cooling is a type of liquid cooling technology that offers several advantages over traditional cooling methods such as air cooling and cold plates. Some of the significant benefits of immersion cooling include:

Types of immersion cooling systems available

There are two types of immersion cooling systems based on the occurrence of a phase change in the cooling liquid during usage: single-phase immersion cooling and two-phase immersion cooling. Each type has its own strengths, and the decision on which one to choose depends on the specific application scenario. Here are the differences between them:

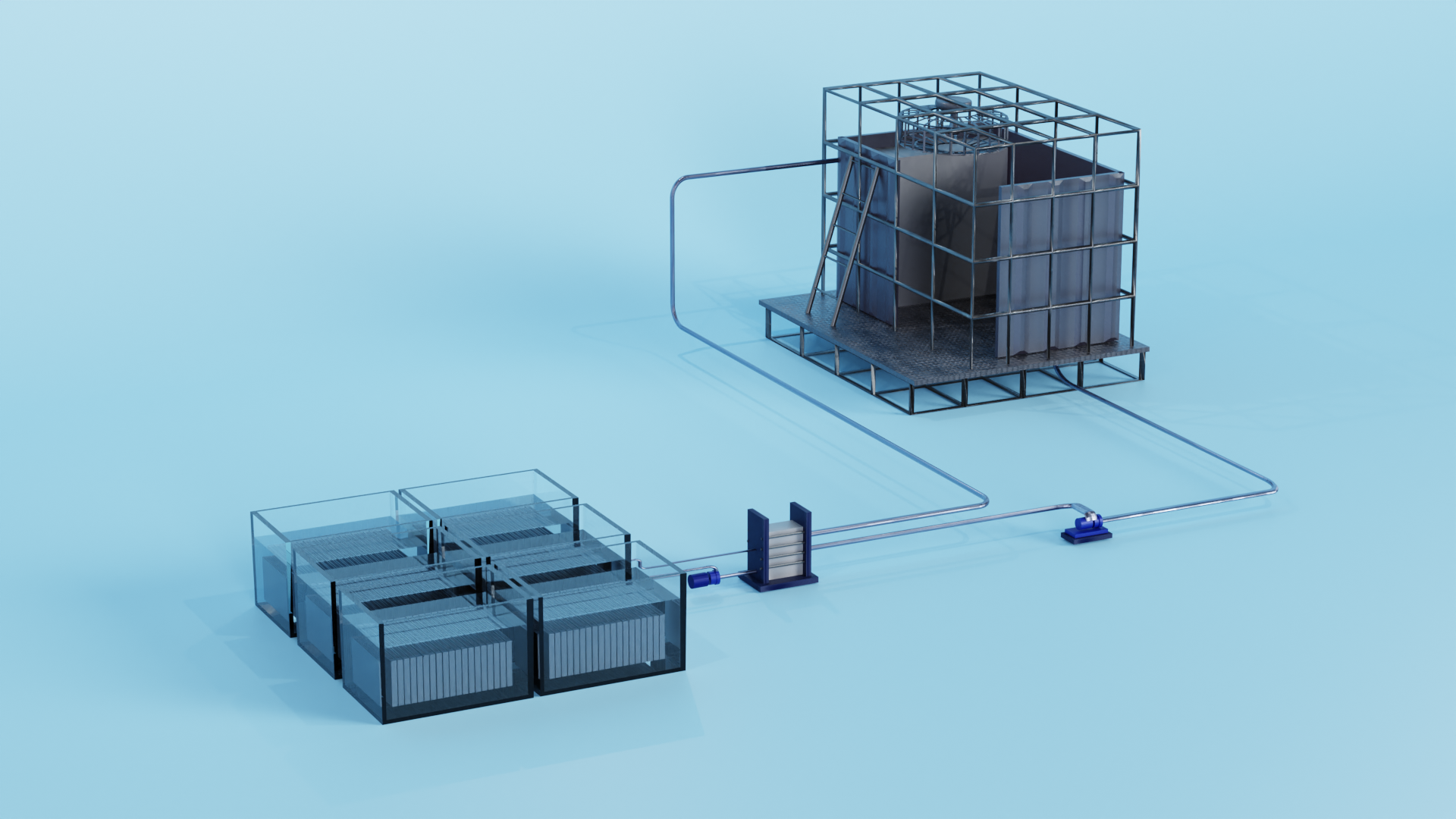

Single-Phase Immersion Cooling

In a single-phase immersion cooling system, the selected coolant usually has a boiling point higher than 100℃, which is higher than the maximum operating temperature of the servers. Therefore, the coolant remains in a liquid state throughout the circulating cooling process without undergoing a phase change. Electronic components are directly immersed in the liquid coolant, facilitating the transfer of heat from the components to the liquid. The heated coolant then circulates to the heat exchanger, cools down, and returns to the cooling tank to continue absorbing heat. This continuous cycle ensures efficient cooling of electronic components.

The advantages of single-phase coolant include lower volatility loss in a closed system, infrequent need for coolant replenishment, good compatibility with electronic components, and high maintainability. However, single-phase immersion cooling has a lower heat dissipation efficiency compared to two-phase immersion cooling.

Two-Phase Immersion Cooling

Two-phase immersion cooling uses coolants with a lower boiling point. In this system, the coolant undergoes a phase change from liquid to vapor. The electronic components are immersed in the coolant, and heat is transferred efficiently as the coolant vaporizes on contact with the components. The rising vapor then condenses on a heat exchanger, releasing heat and turning back into a liquid. This condensed coolant flows back to the cooling tank to repeat the process. Two-phase immersion cooling provides higher heat dissipation efficiency due to the phase change of the coolant. However, it requires careful management of the coolant and may need more maintenance compared to single-phase immersion cooling.

What options are available for liquid coolants in immersion cooling systems?

Liquid coolants are a critical component of immersion cooling technology, and there are several options to choose from. The selection of coolant has become a widely discussed topic in the industry, considering the important characteristics it needs to possess. There are three popular types of immersion coolants available in the market: organosilicons, hydrocarbons, and fluorocarbons.

Organosilicon

Organosilicons, such as silicone oil, are known for their temperature resistance, stability, and safety in low oxygen environments. They have low surface tension and viscosity, enabling effective wetting of contact surfaces. However, they have higher sealing requirements, and those with high boiling points may have flash points, necessitating explosion-proof facilities and safety measures. Toxicity impact and residue after evaporation also need to be considered.

Hydrocarbon

Hydrocarbon coolants are relatively inexpensive, have a high boiling point, and are environmentally friendly. However, they have limited heat transfer capability, making them suitable for high-temperature-resistant equipment. They also have a flash point, requiring cautious handling due to flammability risks.

Fluorocarbons

Fluorocarbons, particularly fluorinated liquids, are widely regarded as the most suitable for data center immersion cooling systems. They exhibit excellent overall heat transfer performance, non-flammability without flash points, chemical inertness, compatibility with various electronic components, and favorable dynamic viscosity for efficient flow and heat dissipation. Common types of fluorocarbons include hydrofluoroethers (HFE), perfluoropolyethers (PFPE), and perfluoroolefins (PFO). PFPEs have low dielectric constants, making them ideal immersion coolants technically. However, they have a high global warming potential (GWP) value, contributing to the greenhouse effect. HFEs have a small impact on the greenhouse effect and are ozone-friendly. They excel in cooling electronic components but may have higher dielectric constants that can affect signal transmission. PFOs offer excellent cooling performance, are non-toxic, and compatible with various materials. They have low ozone depletion potential (ODP) and GWP values, meeting environmental requirements. Their wide boiling point range caters to the needs of different immersion cooling methods. While fluorocarbon compounds used to be expensive due to supply chain reasons, technological advancements and increased production capacity have significantly reduced their prices in recent years.

Introducing Yuji Fluorinated Liquid: The Perfect Immersion Coolant Solution

The Beijing National Convention Center hosted the 18th China Internet Data Center Conference (IDCC2023) in December 2023. This significant event brought together experts from the Data Center industry to discuss the latest trends and future prospects of the digital economy.

At the conference, there was a notable display by Shanghai Yuji Sifluo Co., Ltd. (“Yuji”) featuring their perfluorocarbon immersion coolant (Fluorinated Liquid). They showcased this coolant by submerging several components of a household computer, including motherboards, CPUs, memory, and power supplies, directly into the coolant after removing the fan. Impressively, the computer functioned flawlessly, maintaining consistent hardware temperatures after being operational for multiple days. As a result, this demonstration installation attracted considerable attention and generated substantial interest among the conference attendees.

The Yuji Immersion Coolant is a clear and see-through liquid that is completely safe to use as it does not catch fire and has no flashpoint. It possesses a remarkably low surface tension, making it easy to spread and flow smoothly. Additionally, it has a thin texture which allows for efficient heat transfer. Moreover, it provides exceptional insulation capabilities and is compatible with various materials. Not only is it environmentally-friendly with zero ODP (ozone depletion potential), but it also has a relatively low GWP (global warming potential) value. Due to its versatility, this fluorinated liquid can be applied in a wide range of cooling scenarios, whether it be single-phase or two-phase immersion liquid cooling. Some of its notable applications include cooling large data centers, 5G base stations, IGBT modules in wind and photovoltaic systems, high-voltage power distribution, and new energy lithium battery packs.

Quanzhou Yuji Advanced Materials Co., Ltd. is a high-tech enterprise founded by international fluorine chemistry scholars. Dedicated to the development and industrialization of fluorinated materials, the company specializes in the manufacturing and applying of new generations of environmentally friendly materials for refrigeration, foaming, solvent cleaning, semiconductor processes, and power insulation alternative gases, and more.

Beyond delivering high-quality products, we are committed to providing innovative solutions to address ozone layer depletion and global warming challenges. With extensive research and development capabilities, we welcome collaborations with customers worldwide.